Scaffolding Systems

UBS scaffolding systems have been well recognized around the world for over eight decades. The innovative engineering solutions and our unique aluminum frame access system has allowed UBS to perform thousands of challenging projects over the years.

The initials, UBS have been renowned for engineering excellence, design and engineering custom scaffold solutions for such projects as The Statue of Liberty, Grand Central Station, Washington Monument, NYC Waterfalls and The Jefferson Memorial.

ST. PATRICK'S CATHEDRAL

A custom designed scaffolding and access solution was required for complete access to all areas of the interior and exterior of St. Patrick's Cathedral.

A custom designed scaffolding and access solution was required for complete access to all areas of the interior and exterior of St. Patrick's Cathedral.

The exterior scaffold consists of the UBS aluminum access scaffolding system with a stepped design to transfer vertical loading to the existing bearing walls of the cathedral through the use of support beams and brackets.

The interior scaffolding consists of the UBS aluminum access system along with a custom designed rolling platform in the main Nave to allow for full access to the domed ceiling while maintaining as much seating as possible.

Aluminum was chosed due to its high strength to weight to weight ratio as well as its resistance to corrosion and rusting given the long term duration of the project.

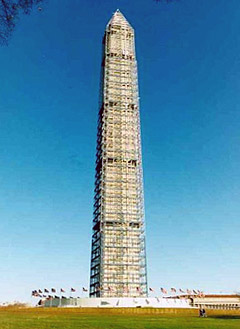

WASHINGTON MONUMENT

This award-winning scaffold stands 565 feet; it was designed, fabricated and erected by UBS in 1999 & 2013. It consisted of 37 miles of aluminum tubing and had a design load in excess of one million pounds to accommodate potential ice and snow loading. The scaffold structure followed the taper of the Monument and is "crowned" with a customized pyramidal structure for the final 65 feet.

This award-winning scaffold stands 565 feet; it was designed, fabricated and erected by UBS in 1999 & 2013. It consisted of 37 miles of aluminum tubing and had a design load in excess of one million pounds to accommodate potential ice and snow loading. The scaffold structure followed the taper of the Monument and is "crowned" with a customized pyramidal structure for the final 65 feet.

In May 2013, UBS completed reinstallation of the scaffolding surrounding the Washington Monument which was required for repairs due to damage that it sustained in the Earthquake of 2011.

STATUE OF LIBERTY

UBS designed and installed scaffolding around the Statue of Liberty in 1984. Along with the scaffolding that made the "Guinness Book of World Records" as the largest freestanding scaffold in the world, UBS designed, fabricated, and installed the special crane in the highest corner tower which safely lifted the old ailing torch to the ground.

UBS designed and installed scaffolding around the Statue of Liberty in 1984. Along with the scaffolding that made the "Guinness Book of World Records" as the largest freestanding scaffold in the world, UBS designed, fabricated, and installed the special crane in the highest corner tower which safely lifted the old ailing torch to the ground.

The project was awarded to UBS at the end of 1983, with work commencing immediately, during what was to be one of the most severe winters the New York area had seen in many years. Our crew of 30 highly skilled workmen had completed the task without serious injury over the next four months. In addition to the highly visible scaffold, we also installed scaffolding along the entire perimeter of the interior shell of the statue, to access the thousands of rusted iron attachments which needed to be replaced due to the corrosive galvanic action between the copper and iron. UBS also designed and built the custom lifting attachments to the torch, the housing for the torch at the base of the scaffolding, the shoring and transfer beams, which safely transmitted the scaffold loading on the museum roof to the foundation below. UBS constructed the work platforms and the long access ramp which brought personnel and material from the dock over the fort walls to the museum level staging deck. UBS installed a personnel/material hoist tower along with a 350 step stair tower that gave access to the top of the statue.

Since the scaffolding could not come in contact with the Statue, UBS designed it as a free standing structure, capable of sustaining 100mph winds. The last tie was placed at the top of the stone pedestal. The aluminum scaffolding was so stable that the torch's six inch movement due to the wind could be measured.

There were 2100 frames and over 20,000 scaffold components used. The self-weight of the scaffolding exceeded 300 tons. It took over a minute for a non-stop hoist tower trip to travel from the staging deck to the top landing. It also took a fit worker over 6 minutes to climb the stair tower to the top.

BASILICA OF THE NATIONAL SHRINE OF THE IMMACULATE CONCEPTION

Incarnation Dome Scaffold Washington, DC

The National Shrine is the largest Catholic Church in the US and ranks amongst the largest in the world. The Shrine's Upper Church has two large domes directly over the Nave floor that required the existing domes plaster finishes removed and replaced with a Portland based material suitable to accommodate the Redemption and Incarnation dome mosaics. Because of year round activities, the Shrine insisted that the Upper Church remain open for regular services throughout the reconstruction. UBS was able to accommodate the Shrine's request by designing a scaffold that would be supported from the Shrine's main columns via two large collector trusses weighing approximately 12,000 pounds each. These trusses would be affixed with an elaborate roller system that would allow the scaffold platform to travel atop of these collectors from the Redemption Dome to the Incarnation Dome.

The National Shrine is the largest Catholic Church in the US and ranks amongst the largest in the world. The Shrine's Upper Church has two large domes directly over the Nave floor that required the existing domes plaster finishes removed and replaced with a Portland based material suitable to accommodate the Redemption and Incarnation dome mosaics. Because of year round activities, the Shrine insisted that the Upper Church remain open for regular services throughout the reconstruction. UBS was able to accommodate the Shrine's request by designing a scaffold that would be supported from the Shrine's main columns via two large collector trusses weighing approximately 12,000 pounds each. These trusses would be affixed with an elaborate roller system that would allow the scaffold platform to travel atop of these collectors from the Redemption Dome to the Incarnation Dome.

THE NEW YORK CITY WATERFALLS

UBS provided the scaffolding for the backbone of the structure on one of the most prestigious art projects that has ever come to New York City. During the Summer of 2008, artist Olafur Eliasson presented the New York City Waterfalls, a temporary monumental public art project commissioned by The Public Art Fund and presented in collaboration with The City of NY. It consisted of four man-made waterfalls at locations within the New York harbor along the shores of Brooklyn, Manhattan and Governor’s Island. This work of art brought nature into an urban cityscape and added a striking element to New York City’s iconic skyline.

UBS provided the scaffolding for the backbone of the structure on one of the most prestigious art projects that has ever come to New York City. During the Summer of 2008, artist Olafur Eliasson presented the New York City Waterfalls, a temporary monumental public art project commissioned by The Public Art Fund and presented in collaboration with The City of NY. It consisted of four man-made waterfalls at locations within the New York harbor along the shores of Brooklyn, Manhattan and Governor’s Island. This work of art brought nature into an urban cityscape and added a striking element to New York City’s iconic skyline.

2004 REPUBLICAN NATIONAL CONVENTION

General Contractor - Turner / Bridge Supplier - Mabey Bridge

UBS designed, furnished, installed and subsequently dismantled and removed the complete pedestrian walkway for the 2004 Republican National convention, linking the Media area inside of the landmarked Farley Post office, with the event itself, located in Madison Square Garden. This included the design and analysis of the walkway and support structure for the bridge and decks themselves, as well as the tent, air conditioning, electrical, facade modifications, and all associated site work.

The overall length of the walkway was approximately 465' with the center span being 140' above the traffic lanes and sidewalks of 8th Avenue. The bridge was assembled in two pieces several blocks away, and driven to site under police escort where it was assembled with an assist crane into its final length and lifted in to place with a 600-ton hydraulic crane. The crane sat directly on top of active Amtrak lines, Pennsylvania Station, and the A and C subway lines, with the outriggers bearing on the landmark Post office foundations, and on the upper concourse level of the steel framing for Madison Square Gardens.